Flooring Basics

Back to: Inspector I Field Basics

Introduction:

When inspecting an insurance loss the flooring in a home could be one of the hardest things to scope. This is because a lot of different types of flooring look similar yet can be made with a completely different material that could vary in cost and functionality. In this lesson, we will examine the different types of flooring and the variations that lie within that type of floor covering as well as the concept of continuous flooring.

Determining Continuous Flooring:

When scoping losses that involve damage to flooring, it is important to note where the flooring transitions. Flooring transitions happen when you switch flooring material, or you add a transition strip in between rooms that have the same flooring material. If there are no breaks at all in the flooring, then that flooring would be continuous flooring no matter if the flooring runs throughout the entire home. An example of transitions or (breaks) between flooring can be seen below.

As we can see this is a transition between floors because there is a transition strip as well as there being two different flooring materials

Although these two flooring types are the same there is a break in the continuous flooring because there is a transition strip in between the rooms.

As we can see here there are not any transition strips between rooms but the flooring breaks into carpet and hardwood in the rooms thus making the floor non-continuous.

Types of Underlayment:

Staple or Nail Down Installation ( installing wood or laminate over wood subfloor): With a staple down or nail down installation over a wood subfloor using solid flooring or engineered flooring, it is recommended that an underlayment of 15lb. a black felt paper is rolled out over the wood subfloor prior to installing the new floor, This hardwood felt paper is necessary to greatly reduce the chance of any moisture coming up through the subfloor and will help protect the hardwood flooring.

Floating Installation ( installing wood or laminate over concrete or tile flooring): There is a multitude of underlayments available for floating installations. They range from simple foam pads to foam pads with a plastic moisture retarder attached to dense felt-like underlayments with remarkable sound absorption properties. Foam pads are typically thinner and their sole purpose is to add a little cushion in between the floor and the subfloor. Foam pads with moisture barriers attached are also on the thinner side but also offer that moisture protection. The denser underlayment pads (usually a felt like material) are typically a bit thicker and offer more support and insulation because of there dense nature. Underlayments pads are especially important for engineered floors or laminate floors which are installed via the floating method over wood or concrete subfloors. When you float an engineered or laminate floor, none of the boards are actually attached to the subfloor. An underlayment is necessary for multiple reasons, floating floors will expand and contract, moving ever so slightly as a whole unit. The smooth surface of the underlayment allows the flooring on top of it to move slightly during seasonal relative humidity changes. Underlayments are also are used under floating floors to act as a cushion, allowing for a bit of a softer feel when walked upon.

Cork Underlayment: Cork underlayments are certainly gaining popularity over synthetic underlayments in both residential and commercial settings. But, what are the major benefits of using a cork underlayment? Cork is a natural product from a renewable source. If you’re looking to go more “green” with your home, cork underlayment is a step in the right direction. Cork underlayment also has superior sound deadening qualities more than most any other synthetic underlayments previously mentioned it also helps to minimize subfloor imperfections, adds a degree of insulation and has anti-microbial properties. Many homeowners with allergies love cork as it is naturally anti-bacterial as well as anti-fungal. It’s important to remember that cork is naturally water resistant, but not waterproof.

Pre-attached underlayment on laminate flooring: Some manufacturers make laminate flooring with an underlayment already attached to the back of each board. This makes installation quick and simple, negating the need to roll out a separate underlayment. Just keep in mind that if this attached underlayment does not have a moisture barrier attached as well it is important to note as this can result in extra charges

Hardwood Flooring:

Hardwood flooring is made from one single piece of hardwood cut from a tree of your choice. Most commonly, you’ll find floors made from oak, cherry, or walnut, but there are several additional solid wood options to choose from.

Generally, planks are three-quarters of an inch thick, but width can vary. The standard width is between three and five inches, and most retailers will call this a “medium” or “standard” plank. Another popular style is wide planks which measure in at between five and ten inches and look beautiful in living spaces throughout the home.

Engineered Wood Flooring:

Engineered hardwood is a more affordable alternative to solid hardwood. Made by combining a top layer of genuine hardwood with multiple layers of ply plank that run in different directions beneath, they look like solid hardwood but have better resistance to moisture. Below you will see a cross-section of this flooring so you can better understand

Laminate Flooring:

Similar in design to engineered wood floors, laminate has a top layer that’s been finished and sealed and is mounted over layers of plywood or compressed fiber

The main difference between laminate and real wood flooring is that the laminate option doesn’t have a real wood top layer. Instead, it’s an image captured using photo-realism technology of beautiful finishes like wood, stone, ceramic tile, or stained concrete that’s covered in a plastic coating

Bamboo Flooring:

Although it falls under the general category of hardwood, most manufacturers put bamboo in a class of its own. The sustainable option has a comparable hardness to oak and is an eco-friendly option for your home.

Natural bamboo produces floors with a very light wood color, but processing treatments are available to give the material a darker finish and make it look like other stained wood options.

The majority of bamboo hardwood is made from Moso bamboo imported from China. The plants, which are actually in the grass family and not a tree, can grow up to over 70 feet high in less than 60 days.

Linoleum:

When most people picture linoleum floors, they picture kitchens from the 1970’s with the slick looking surface. Luckily, the option has come a long way since then, and there are many attractive choices available.

Made from renewable, biodegradable materials like linseed oil and cork, linoleum is considered an environmentally friendly material.

It comes in sheets, and to install it you glue them directly to the floor. The sheets feature mineral pigments that create a variety of rich colors and patterns, and they may be sealed with a protective coating to prevent staining and wear.

Cork Flooring:

Aesthetically, it has the same warm appearance as wood but with unusual grain patterns that sometimes include speckles and swirls in the pattern. You can purchase it in either tiles or planks, and it’s constructed similarly to laminate with a top layer that’s glued to a stable core material underneath.

Ceramic Tile:

Ceramic tile is one of the most versatile flooring types. Its many colors, textures, shapes, and sizes make it useful in just about any space. The tiles are made by combining a mixture of clay and shale and then firing it in a kiln to harden the ceramic. Pigments added to the compound give you a variety of color choices in ceramic tile.

There are four different types of ceramic tiles to choose from.

a. Glazed Ceramic

Glazed ceramic tiles have a glossy coating that gets applied before they fire the file. This creates a glass-like finish and makes them easy to maintain.

b. Quarry Tile

:max_bytes(150000):strip_icc()/quarry-tiles-139678125-5a983146fa6bcc00376b7b8b.jpg)

These are unglazed tiles that get their color from pigments added directly to the clay mixture.

Quarry tiles usually have a slightly rough texture and provide more resistance against slips and fall when they are wet than glazed tiles.

c. Porcelain Tile

Porcelain tiles are available in both glazed and unglazed varieties and are one of the most durable tile choices. They are fired at very high temperatures making them harder than other tile types.

d. Terracotta Tile

Terracotta tile is another variety of unglazed tile that’s common in outdoor spaces or homes with earthy or rustic decor schemes. This is the least durable type of tile, and if you choose to install it, you’ll want to seal it periodically to guard against staining over time.

With so many different options in ceramic tile, it’s difficult to estimate pricing. Some tiles sell for $1 per square foot, while others may cost $100. If you want professional installation for your project, you’ll pay $4 to $12 per square foot depending on the level of difficulty.

Stone Tile:

Floor tiles are made from many different types of stone including marble, travertine, ledger, granite, slate, and limestone. The softer stones like sandstone won’t resist moisture as well as harder stone like granite or marble.

a. Marble Tile

Marble is the unparalleled champion of stone texture and appearance. Many forms of marble have contrasting vein and base colors that make this stone synonymous with high-end, chic decor

b.Granite

Granite is probably the most popular stone tile because it combines good durability and bolder colors and textures at an affordable price. Few natural stones are able to offer this kind of quality and practicality

c.Slate –

A good durable natural stone, slate tile floors are also extremely versatile in that you can find almost any color or texture in slate.

d.Sandstone –

e.Engineered Stone –

A combination of quartz and resin, this stone isn’t a true natural stone, but it is a more durable and cheaper alternative. It can offer similar appearances to natural stone but tends to lack their more definitive grains.

Carpet-

Carpeting is another common and versatile option. It comes in more colors and textures than any other potential choices and is woven from a variety of materials.

To determine the quality of the carpet, look for the fiber density count. The more fibers it has per square inch, the more durable the product will be.

Below you will see just a few of the common carpet types you may encounter in the field

a. Wool

Considered the standard of quality for carpet, wool is a naturally moisture resistant material that’s both durable and able to ward off stains. It feels good against hands and feet and is the most popular choice.

b. Nylon

Another option that stands up well against wear and tear, Nylon is a synthetic fiber known for being strong. It is known for building up static electricity, so be sure that the product you buy has been treated to reduce those effects.

c. Acrylic

A second synthetic option, Acrylic closely mimics the properties of wool. It stands up well against wear and mildew, and naturally wards off insects.

d. Polyester

Polyester is a popular material if you’re looking for carpeting in bold, bright colors. It’s moisture resistant, but if you stain it, beware that it will be difficult to remove.

e. Polypropylene

If you’re looking for an option that can stand up to indoor/outdoor living, a carpet made from polypropylene might be the right choice. It’s the most resistant to stains, moisture, and mildew, and if you install it without a carpet pad, it will work well in an outdoor space.

Vinyl Flooring:

Vinyl tiles and sheets are known as resilient flooring. They provide a flexible and cushioned floor surface that is durable and maintenance-free. This flooring type is constructed by attaching the top wear layer to a layer of felt and foam.

Baseboard Types:

Baseboards cover the portion of the joint where the wall and floor intersect. They are usually between 3 to 5 inches in height, so when inspecting it is important to list this height in the video. They also serve to make a smooth transition between the floor and the wall. In certain flooring types, such as laminate, they also serve to cover up the gaps between the laminate strips and the wall.

Baseboard molding is constructed from a number of different materials. Below we will see a few different types

Medium Density Fiberboard:

Medium density fiberboard (MDF) is the most common type of baseboard molding. It is an engineered wood product made by combining wood fibers together with pressure treatment. The advantages of MDF are that it is cheap and can be painted easily. However, it has no natural wood grain

Pine Baseboard:

Pine molding is manufactured from pine trees, so it has the look and feel of real wood. It is also the least expensive of the natural woods. However, the structure of pine wood gives it an inconsistent consistency, where certain parts of the molding may be harder than others.

Oak

Although more expensive than pine, oak is an excellent baseboard molding choice where the wood is to be stained and varnished. Most hardware stores carry a supply of oak, while other hardwoods such as birch and maple may be harder to find.

Vinyl

Vinyl is another type of molding available. Its use in residential installations is mostly in utility rooms and basements. It comes in rolls and is held in place with industrial strength glue.

In between the floor and the baseboard, there is usually space, to fill this space most people use one of the two trims below5:

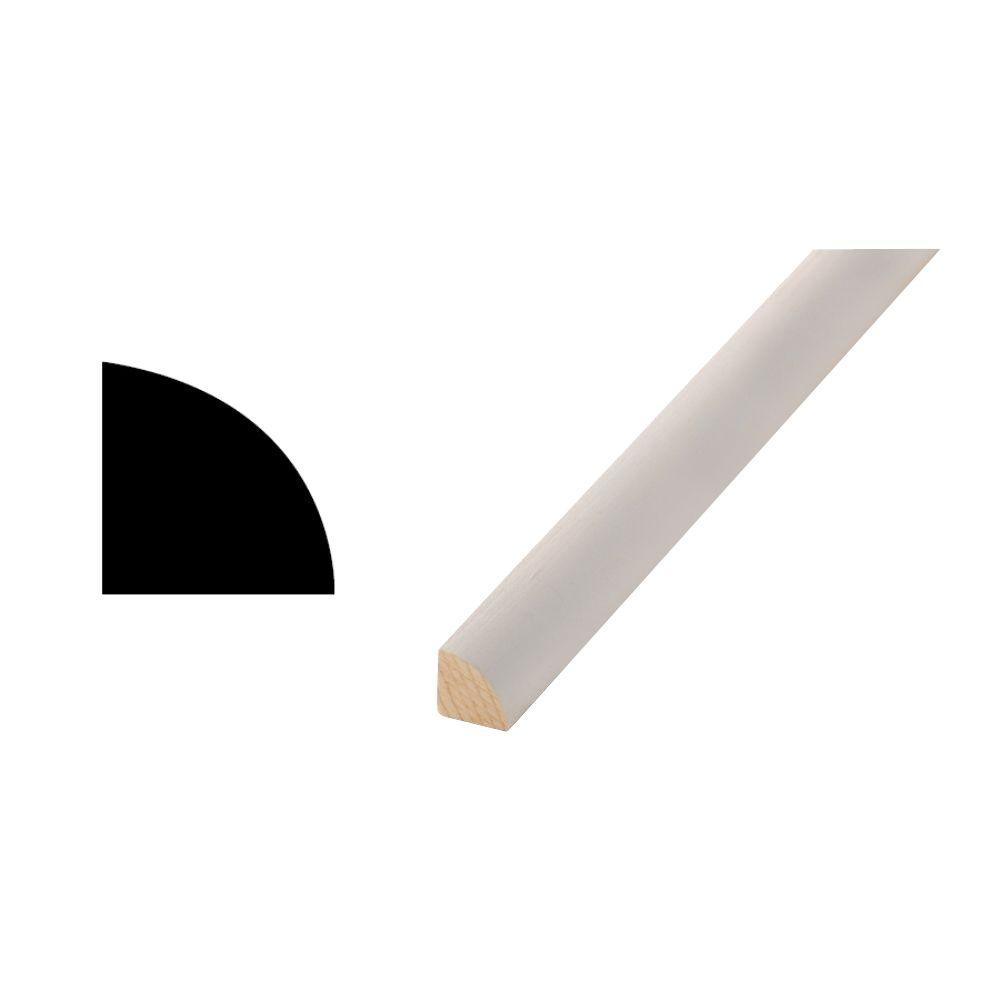

Quarter Round:

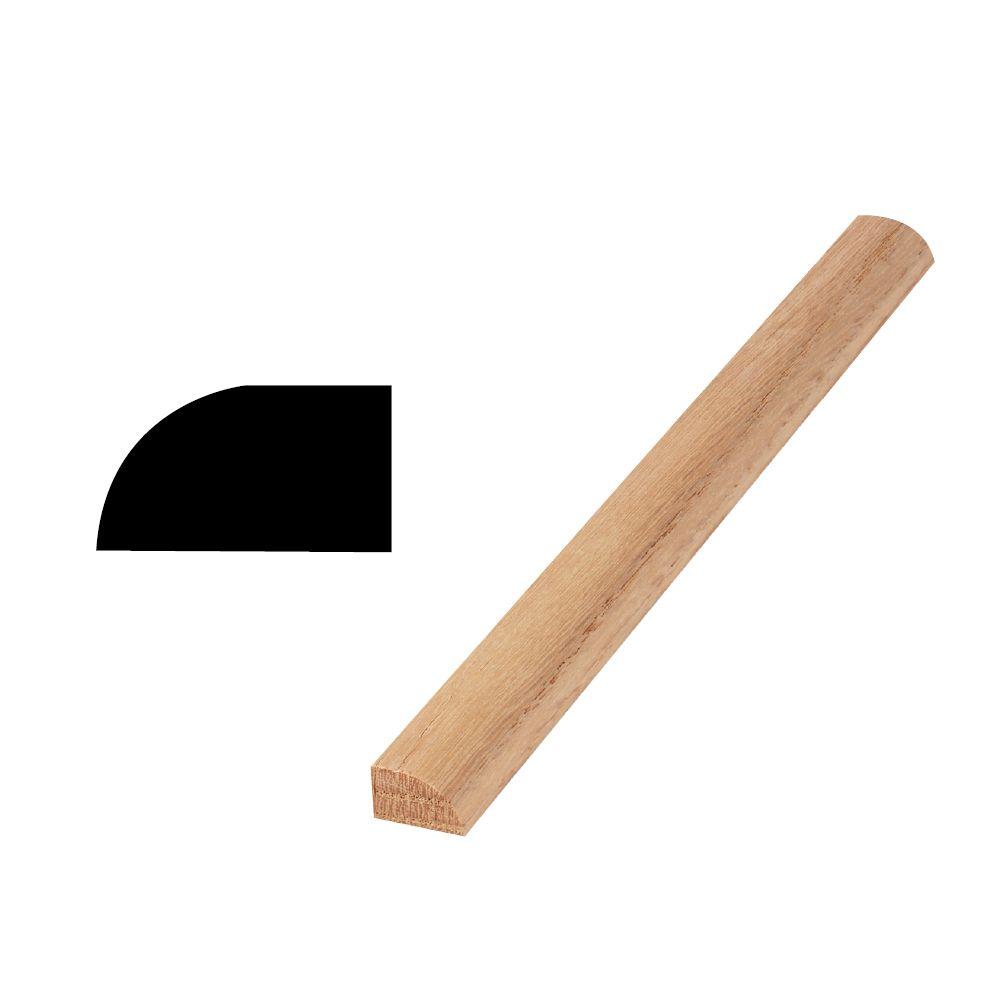

Shoe Base Molding:

Leave a Reply

Want to join the discussion?Feel free to contribute!