Interior Construction Basics

Back to: Inspector I Field Basics

Interior Construction Essentials for Inspectors

Introduction: When inspecting an insurance loss it’s important to know the basics of construction. This lesson is designed to not help just you but also your fellow estimator and desk adjuster to understand the details of a loss. When inspecting a loss always make sure to over-inspect rather than not scoping enough. Because we handle claims in a non- traditional manner, it is crucial that our estimators and desk adjusters get any and all details of a loss because they will not actually see the loss. In this lesson, we will cover common drywall types, drywall textures, insulation types, that you will see in the field as an inspector.

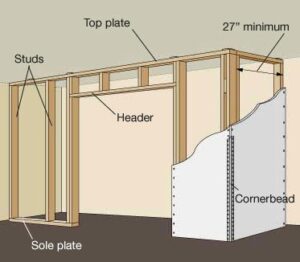

An interior wall is typically built from 2-by-4 or 2-by-6 wall studs and framing, covered with panels of drywall that are nailed or screwed to the framing members.

Types, thickness’, and common applications of Drywall:

Regular Drywall or White Board

Regular drywall is normally white on one side and brown on the other side. It probably is the most economic drywall type and comes in different sizes ranging in thickness from 3/8 inch to 1 inch. Typically when this drywall is hung on the ceiling it is a 1/2 inch thickness and when hung on the walls it is 3/8 inch in thickness. This is the most common drywall used and normally is available in 4 x 8 panels.

Green Board Drywall

Green board drywall is also known as moisture resistant drywall. It has a green covering that makes it more moisture resistant than regular drywall. It is somewhat more expensive than regular drywall, but be aware that it is not waterproof, so don’t use it if it’s going to be in contact with water. Also used as a tile backer in limited wet areas, e.g., bathroom and basement walls, plus kitchens, and laundry and utility rooms.

Blue Board Drywall

Blue board drywall is also known as plaster baseboard. Blue board is used for veneer plastering, and the surface paper has special absorption qualities. It has a high water and mold resistance and there are fewer steps involved in veneer plastering. Blue board drywall is not made for mud, tape, and paint and is typically used in bathrooms or places with a lot of moisture.

Paperless Drywall

Paperless drywall has been replacing paper drywall in recent years. This type of drywall is covered with fiberglass instead of paper, which protects the gypsum board from rot and offers even greater resistance to mold and mildew. The quality of the board is a little tougher than regular drywall, however, some construction pros find it easier to cut. Remember that you need to take extra steps when dealing with fiberglass materials. Paperless drywall has some slight textures that will require applying joint compound to achieve a smooth finish

Purple Drywall

Purple drywall is an more moisture resistant product that offers the same advantages of regular drywall, but with superior moisture and mold resistant characteristics. It might be installed on all wall and ceiling applications and is ideally suited where enhanced moisture and mold resistance is desired. If the drywall is going to be in contact with water, this is the drywall that should be used.

Type X Drywall

Type X is the so-called fire-resistant drywall. Several thicknesses can be used in layers to achieve higher fire rating. It is harder to cut and work than regular drywall and normally is used in garages, rooms and apartment buildings, as it is required by several building codes. Type X drywall is made with special noncombustible fibers. It normally comes in 5/8 thickness and its extra thickness can also improve its soundproofing characteristics.

Sound Proof Drywall

Drywall Textures and Wall Panneling –

Drywall textures are textures that people apply to their walls and ceilings to give them a more unique look. It is important to know the different types of textures as their not always evident in videos and can sometimes be overlooked by an inspector, however, these details are necessary in order to indemnify an insured.

A. Popcorn – A “popcorn” or “cottage cheese” ceiling is a little heavier and a little more unique than what is traditionally used on ceilings. It helps with sound dampening but has become increasingly less popular in recent years. This is because it can be difficult to paint and is often accused of collecting dust.

B. Comb – “Comb” textures are great for creating lines and strips of different widths to product dimensional texture effects on surfaces. It almost has an oriental feel to it.

C. Orange Peel – One of the most common drywall texture methods is the basic Perlite. It is often called the “orange peel” because of it’s strong resemblance to the skin of the fruit and can vary from a series of small blobs of splatter to an overall fine spray.

D. Knockdown – The “knockdown” is one of the more subtle drywall texturing techniques. It closely resembles a stucco finish. It can hide a wall’s imperfections while adding warmth, character, and a subtle depth to a room.

E. Sand Swirl – The “sand swirl” pattern can also be used on both walls and ceilings. It’s quite popular and another common way to add interest to a home.

F. Slapbrush – The “slapbrush” drywall texture method is one of the messiest to produce, but is well worth the effort. The method is also known as “stomp brush” texture, “crows feet” texture, “tiger skin” texture, or “panda paws” texture. It’s very popular and especially forgiving on walls with imperfections.

Wall Paneling: Wall paneling is also a common choice among homeowners as it adds a decorative look that cant be achieved with drywall texturing.

Decorative Wall Panels

Decorative wall panels are available in many different materials. They are often used to change the look of the wall, but may also be installed to help protect the wall from damage. Wainscoting is one of the most commonly used wall panels that is seen above. It is made from wood or synthetic materials patterned with carvings and designs. Wainscot is usually installed on the lower half of a wall, but heights and styles may vary. Pre-fabricated panels may be used, or those familiar with woodworking can create their own versions. Other common materials used for decorative paneling include laminate, stainless steel, and plastics.

Beadboard:

Beadboard is simply another type of tongue-and-groove paneling, except that the tongues and grooves connect not single boards but panels with the distinctive look of a beaded-board plank.

Board and batten:

There are two types of board and batten that you will see in the field and they are polar opposites so it is important to note which is installed should you come across it. The first type is real wood panels on top of which the board and batten framework is formed with solid wood battens (strips) and boards (planks). And then there’s the imitation-style board and batten, which is created atop plyboard or even drywall rather than real wood panels.

Shiplap paneling:

This type of paneling is usually laid horizontally, and it acquired its name as its panels overlap, with grooved boards called “rabbets” fitting together tightly to form a weatherproof seal.

Tongue and groove:

Tongue and groove are very similar to shiplap and offers the same clean, classic look. The difference is in the way the boards connect; while shiplap panels are joined with a rabbet joint at the top and bottom of each board, tongue and groove paneling connects where the “tongue” of one board fits into the “groove” of another. In this way, shiplap presents the look of the boards overlapping slightly whereas tongue and groove boards just fit one on top of the other.

Tileboard

Tileboard panels are made from melamine or resin and are used to mimic the look of ceramic tile. They are textured and colored to look like tile and are attached to a moisture-resistant backer board.

Utility Paneling

Utility paneling, often called pegboard, is made from perforated hardboard and is used for its function and appearance. These panels contain rows of small holes that can be used to hang objects from nails or pegs. They are frequently used in kitchens or garages, as well as in commercial applications. Utility paneling is available in standard white or natural wood finishes and also in custom colors. These panels can be installed over the entire wall or just in small areas as needed.

Acoustical Panels

Acoustical panels are used to control noise levels in a space and to block noise transfer through walls. They’re made from foam or wood cores wrapped with a layer of vinyl or fabric. The panels help absorb sound and are commonly used in movie rooms and in-home music studios. These panels are available in a wide variety of colors and textures to match the room’s decor. Acoustical panels can be installed temporarily using clips or magnets, or with nails or adhesive for more permanent applications.

Structural Wall Panels

While most types of wall paneling are installed on the interior, Structural wall panels are used to create exterior walls. These panels are frequently made from precast concrete and allow for quick and easy framing of homes and businesses. Some structural panels may be used to replace both interior and exterior walls. Structural insulated panels (SIPs) take the place of wall framing, interior drywall, and exterior sheathing or siding. They are made from sheets of rigid foam insulation sandwiched between layers of wood fiberboard.

Insulation-

An insulating material’s resistance to conductive heat flow is measured or rated in terms of its thermal resistance or R-value — the higher the R-value, the greater the insulating effectiveness. The R-value depends on the type of insulation, its thickness, and its density

The most common insulation materials are fiberglass, cellulose, and foam. Insulation types include loose fill, batts, rolls, foam board, spray board, and vapor barriers. When inspecting a loss if there is drywall damage it is important to not only determine which type of drywall the home has but also the material and type of insulation behind that drywall.

Insulation Types:

Blown-in/Loose fill insulation–

Blown in insulation is usually made of fiberglass or cellulose (recycled paper fiber) that is blown or sprayed into place with pneumatic equipment. This insulation type is common for hard-to-reach areas such as attics, it is also used in wall cavities and can be installed over existing insulation

Insulation Batts:

Insulation Batts are pre-cut sections of fiberglass or rock wool insulation. This form of insulation is Designed for easy handling and use between framings, such as studs and joists. Batts are available either with or without paper or aluminum foil facing and can be used in floors, walls, attics, and ceilings.

Insulation Rolls:

Insulation rolls are available in pre-cut widths to fit between studs and joists. This insulation comes in continuous lengths ranging from 20 to 40 linear feet that are Ideal for attics, floors and other areas where longer runs are needed.

Foam Board Insulation:

Foam Board Insulation is basically just rigid panels of insulation. This insulation can be used to insulate almost any part of a home, from the roof down to the foundation. Polystyrene and polyurethane are the most common types of materials used in making foam board insulation. This insulation reduces heat conduction through structural elements like wood and steel studs.

Spray Foam Insulation:

Latex or polyurethane spray foam insulation is sprayed into place with a spray can or specially designed equipment. This insulation can be used to fill small gaps and cracks and is Ideal for sealing around doors, windows, and vents.

Vapor Barriers:

Usually composed of a thin film, such as polyethylene, vapor barriers are used to retard or prevent water vapor diffusion into a wall, ceiling or floor during the cold winter.

/GettyImages-510926034-5aeb60bc30371300365c6c33.jpg)

/2080893961-drywall-in-the-bath-58f2f4145f9b582c4df9353b.jpg)

/GettyImages-700724589-5aeb6004eb97de003650ab3d.jpg)

/3654072216-drywall-covering-58f2f3913df78cd3fc5f0fc1.jpg)

/wall-lumber-company-drywall4-58f2f6df5f9b582c4d006fd8.jpg)

/drywallsound-58f2f7b93df78cd3fc6a3189.jpg)

Leave a Reply

Want to join the discussion?Feel free to contribute!